Product Description

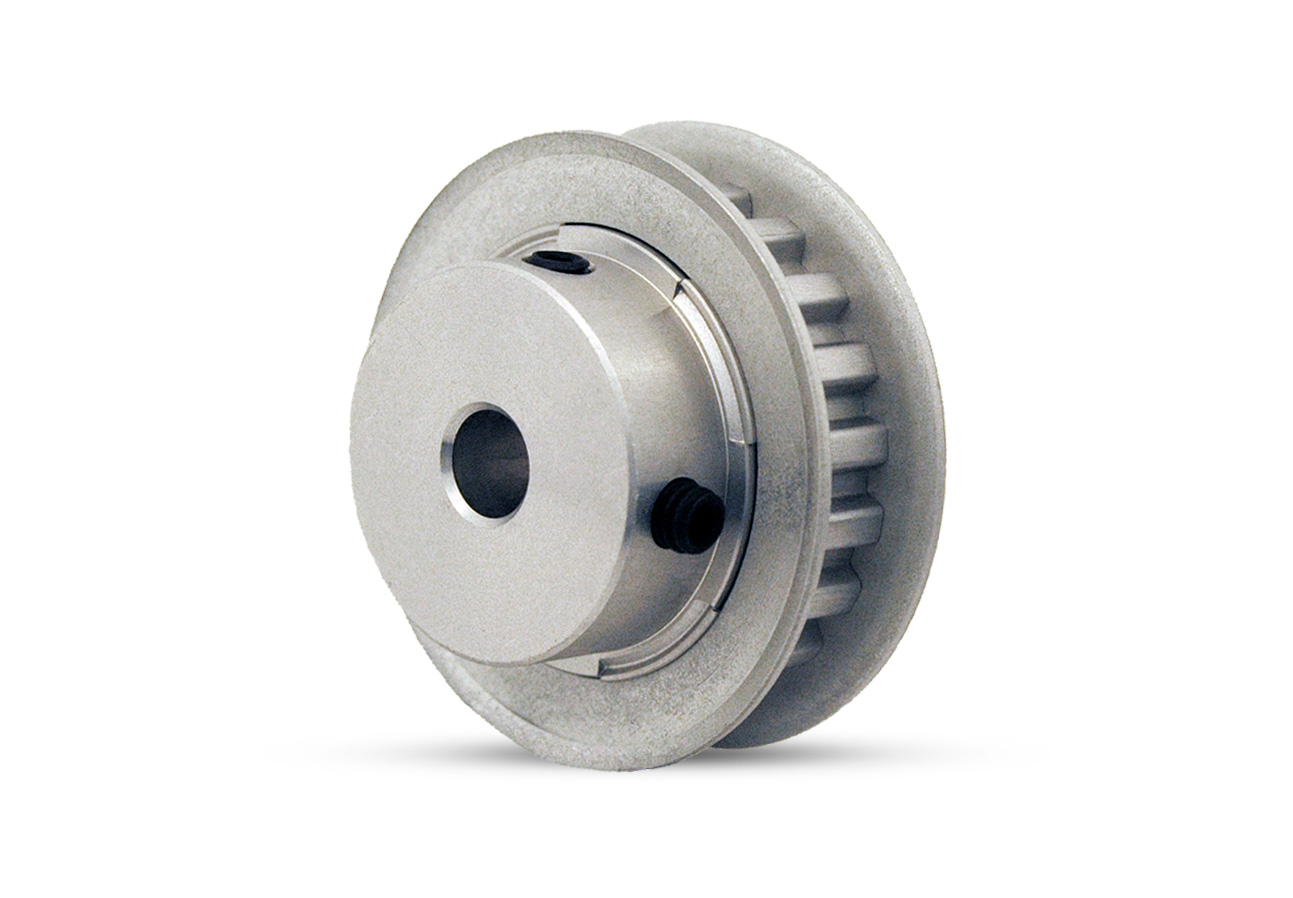

1.5GT GT2 3GT 5GT 3M S3M 5M S5M MXL XL T5 T2.5 100 110 Teeth Timing Belt and Timing Pulley

1. Teeth Type: T2.5,T5,T10,T20,MXL,XL,L,H,XH,XXH,XXL,SL9,SL12,SL,HTD:3M,5M,8M,14M,20M, STPD/STS type(S2M,S3M,S4.5M,S5M,S8M,S14M) GT2 AND SO ON

2. Material: aluminum, carbon steel, brass and nylon available.

3. Surface treatment: blacken, anodize, zinc-plating and so on

4. Tolerance: conform to customers requirement

5. OEM/ODM service offered

HangZhou CHINAMFG Industry Co., Ltd. is a specialized supplier of a full range of chains, sprockets, gears, gear racks, v belt pulley, timing pulley, V-belts, couplings, machined parts and so on.

Due to our CHINAMFG in offering best service to our clients, understanding of your needs and overriding sense of responsibility toward filling ordering requirements, we have obtained the trust of buyers worldwide. Having accumulated precious experience in cooperating with foreign customers, our products are selling well in the American, European, South American and Asian markets.Our products are manufactured by modern computerized machinery and equipment. Meanwhile, our products are manufactured according to high quality standards, and complying with the international advanced standard criteria.

With many years’ experience in this line, we will be trusted by our advantages in competitive price, one-time delivery, prompt response, on-hand engineering support and good after-sales services.

Additionally, all our production procedures are in compliance with ISO9001 standards. We also can design and make non-standard products to meet customers’ special requirements. Quality and credit are the bases that make a corporation alive. We will provide best services and high quality products with all sincerity. If you need any information or samples, please contact us and you will have our soon reply.

HangZhou CHINAMFG Industry Co., Ltd. is a specialized supplier of a full range of chains, sprockets, gears, gear racks, v belt pulley, timing pulley, V-belts, couplings, machined parts and so on.

Due to our CHINAMFG in offering best service to our clients, understanding of your needs and overriding sense of responsibility toward filling ordering requirements, we have obtained the trust of buyers worldwide. Having accumulated precious experience in cooperating with foreign customers, our products are selling well in the American, European, South American and Asian markets. Our products are manufactured by modern computerized machinery and equipment. Meanwhile, our products are manufactured according to high quality standards, and complying with the international advanced standard criteria.

With many years’ experience in this line, we will be trusted by our advantages in competitive price, one-time delivery, prompt response, on-hand engineering support and good after-sales services.

Additionally, all our production procedures are in compliance with ISO9001 standards. We also can design and make non-standard products to meet customers’ special requirements. Quality and credit are the bases that make a corporation alive. We will provide best services and high quality products with all sincerity. If you need any information or samples, please contact us and you will have our soon reply.

FAQ:

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 10 workdays.

2.Production Lead-times: 20-40 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we’ll check.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Timing Pulley |

| Manufacturing Process: | Machined |

| Material: | Al,C45 |

| Surface Treatment: | Oxygenation |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 60/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What environmental factors should be considered when using XL pulleys outdoors?

When using XL pulleys outdoors, several environmental factors should be taken into consideration. Here is a detailed explanation of the factors that should be considered:

1. Moisture and Water Exposure:

Outdoor environments often expose XL pulleys to moisture and water, such as rain, humidity, or even direct water contact. It is crucial to consider the pulleys’ resistance to corrosion and rust in such conditions. Choosing pulleys made from materials with high corrosion resistance, such as stainless steel or coated alloys, can help prevent damage and ensure long-term performance.

2. Temperature Variations:

Outdoor environments may subject XL pulleys to temperature variations, including extreme heat or cold. Different materials exhibit varying thermal properties, so selecting pulleys with suitable temperature resistance is essential. Pulleys made from materials that can withstand the anticipated temperature range will help prevent deformation, cracking, or premature wear due to thermal expansion or contraction.

3. UV Radiation:

XL pulleys used outdoors are exposed to ultraviolet (UV) radiation from sunlight. Prolonged exposure to UV radiation can cause material degradation, discoloration, or loss of mechanical properties. Choosing pulleys with UV-resistant coatings or materials that are specifically formulated to withstand UV radiation can mitigate these effects and ensure the longevity and performance of the pulleys.

4. Dust and Particulate Matter:

Outdoor environments often contain dust, dirt, and other particulate matter that can accumulate on XL pulleys. The presence of debris can lead to increased friction, wear, and decreased performance. Choosing pulleys with smooth surfaces, effective seals, or protective covers can help minimize the ingress of dust and particulate matter, reducing the risk of damage and maintaining optimal operation.

5. Chemical Exposure:

In certain outdoor applications, XL pulleys may come into contact with chemicals, such as solvents, cleaning agents, or environmental pollutants. It is crucial to consider the chemical compatibility of the pulley materials with the substances present in the environment. Selecting pulleys made from chemically resistant materials or applying protective coatings can prevent chemical reactions, degradation, or premature failure.

6. Vibrations and Mechanical Stresses:

Outdoor environments may subject XL pulleys to vibrations and mechanical stresses caused by factors like wind, machinery vibrations, or uneven terrain. It is important to ensure that the pulleys are designed and installed to withstand these forces. Reinforcing the pulleys with appropriate structural features, such as additional ribs or thicker walls, can enhance their durability and prevent mechanical failures.

7. Maintenance and Inspection:

Outdoor XL pulleys may require more frequent maintenance and inspection compared to indoor applications. Regular cleaning, lubrication, and inspection of the pulleys can help identify and address any environmental damage or wear in a timely manner. Implementing a maintenance schedule and following manufacturer-recommended guidelines will ensure the pulleys remain in optimal condition.

By considering these environmental factors when using XL pulleys outdoors, it is possible to select pulleys that are specifically designed and constructed to withstand the challenges posed by the outdoor environment. This ensures reliable performance, longevity, and minimal downtime in outdoor applications.

How do advancements in material technology influence the design of modern XL pulleys?

Advancements in material technology have a significant impact on the design of modern XL pulleys. Here’s a detailed explanation of how these advancements influence their design:

1. Enhanced Durability:

New materials with improved strength and durability allow for the design of XL pulleys that can withstand higher loads, operate at higher speeds, and have increased resistance to wear and fatigue. Advanced materials, such as high-strength alloys, composites, or specialized polymers, provide superior mechanical properties, enabling the design of more robust and long-lasting pulleys.

2. Weight Reduction:

Lightweight materials, such as carbon fiber composites or engineered polymers, contribute to the design of lightweight XL pulleys. Reduced weight in pulley systems offers advantages such as improved energy efficiency, reduced inertia, and lower overall system weight. This is particularly beneficial in applications where weight reduction is critical, such as aerospace, automotive, or portable machinery.

3. Corrosion Resistance:

New materials with excellent corrosion resistance properties, such as stainless steel or corrosion-resistant coatings, enable the design of XL pulleys suitable for harsh or corrosive environments. Corrosion-resistant pulleys are essential in industries such as marine, chemical processing, or outdoor applications where exposure to moisture, chemicals, or saltwater can cause degradation and premature failure.

4. Temperature Resistance:

Advancements in material technology have led to the development of materials that can withstand extreme temperatures. For applications involving high or low temperature environments, such as industrial ovens, furnaces, or cryogenic systems, the use of materials with superior temperature resistance ensures the pulleys maintain their performance and integrity under challenging operating conditions.

5. Noise and Vibration Damping:

New materials with inherent damping properties, such as elastomers or composite laminates, contribute to the design of XL pulleys that can effectively reduce noise and vibrations during operation. This is particularly important in applications that require low noise levels or where excessive vibrations can affect the performance and reliability of the system.

6. Customization and Flexibility:

Advancements in material technology provide designers with a wider range of options to tailor the properties of XL pulleys to specific application requirements. Materials can be formulated or engineered to meet specific needs such as high friction coefficients, electrical conductivity, or resistance to specific chemicals. This customization and flexibility in material selection allow for the optimization of pulley design and performance for various applications.

Overall, advancements in material technology have revolutionized the design of modern XL pulleys by offering improved durability, reduced weight, corrosion resistance, temperature resistance, noise and vibration damping, and customization options. Manufacturers can leverage these advancements to develop pulleys that meet the evolving needs of diverse industries and deliver enhanced performance and reliability.

What is an XL pulley, and how does it differ from other pulley types?

An XL pulley is a specific type of pulley commonly used in power transmission systems. It belongs to the family of timing belt pulleys, which are designed to work in conjunction with timing belts for precise motion control. Here are the key characteristics and differences of XL pulleys compared to other pulley types:

1. Tooth Profile:

XL pulleys have a tooth profile that is compatible with XL timing belts. The tooth profile is designed to accurately engage with the corresponding teeth on the timing belt, ensuring precise and synchronous motion transfer. The tooth profile of an XL pulley typically has a trapezoidal shape with a specific pitch and tooth height, which differs from other pulley types.

2. Pitch Size:

The pitch size of an XL pulley refers to the distance between adjacent tooth centers. XL pulleys have a pitch size of 0.200 inches (5.08 mm). This pitch size is standardized and ensures compatibility with XL timing belts of the same pitch, allowing for easy interchangeability and system design flexibility.

3. Belt Width Compatibility:

XL pulleys are designed to accommodate XL timing belts of specific widths. The belt width is determined by the application requirements and load considerations. XL pulleys are available in various groove widths to match the corresponding XL timing belt width, ensuring proper belt engagement and power transmission.

4. Material and Construction:

XL pulleys are commonly made from materials such as aluminum, steel, or plastic, depending on the application requirements. The choice of material affects the pulley’s durability, weight, and resistance to wear. The pulleys are typically precision-machined to ensure accurate tooth profiles, smooth operation, and reliable performance.

5. Application Range:

XL pulleys are widely used in applications that require precise motion control, such as robotics, CNC machines, 3D printers, and other automated systems. They are suitable for moderate to high torque requirements and can handle a range of speeds and loads, depending on the specific pulley size, material, and construction.

6. Interchangeability:

One of the advantages of XL pulleys is their interchangeability. Since they adhere to standardized pitch sizes and tooth profiles, XL pulleys from different manufacturers can be used interchangeably with XL timing belts of the same specifications. This interchangeability simplifies replacement, maintenance, and system upgrades.

In summary, an XL pulley is a type of timing belt pulley designed for precise motion control. It differs from other pulley types in terms of its tooth profile, pitch size, belt width compatibility, material and construction, application range, and interchangeability. Understanding these differences is crucial for selecting the appropriate pulley type for specific power transmission requirements.

editor by CX

2024-03-30