Product Description

Product Description

|

Product Type |

XL, H, HTD8M,5M,3M, AT3, AT5 standard gear, or according customer drawing to make. |

|

Material: |

Carbon Steel, Brass, Aluminium, Stainless steel, Plastic, POM, Delrin, Titanium Alloy etc. |

|

Process method |

CNC Turning, hobbing gear |

|

Surface finish: |

Chrome plating, Anodization, Powder coating, blackening, Sand blasting, Brushing & ploshing,Electrophoresis etc. |

|

OEM & ODM Service |

Available |

|

Design Software |

PRO/E, Auto CAD, Solid Works |

|

Trade Terms: |

FOB,,CIF,EXW |

|

Payment Terms: |

T/T, L/C, |

|

Packing: |

Foam, Carton, Standard Wooden boxes |

|

Capacity |

8,000~1,5000 pcs per month |

|

Delivery |

20-30 days after receiving PO |

|

Applications |

Automotive Parts,hydraulics, compressors,Industrial equipments, transmission parts, etc. |

|

Our services: |

CNC Machining, Milling, Stamping, Sheet metal fabricating, and Die-Casting |

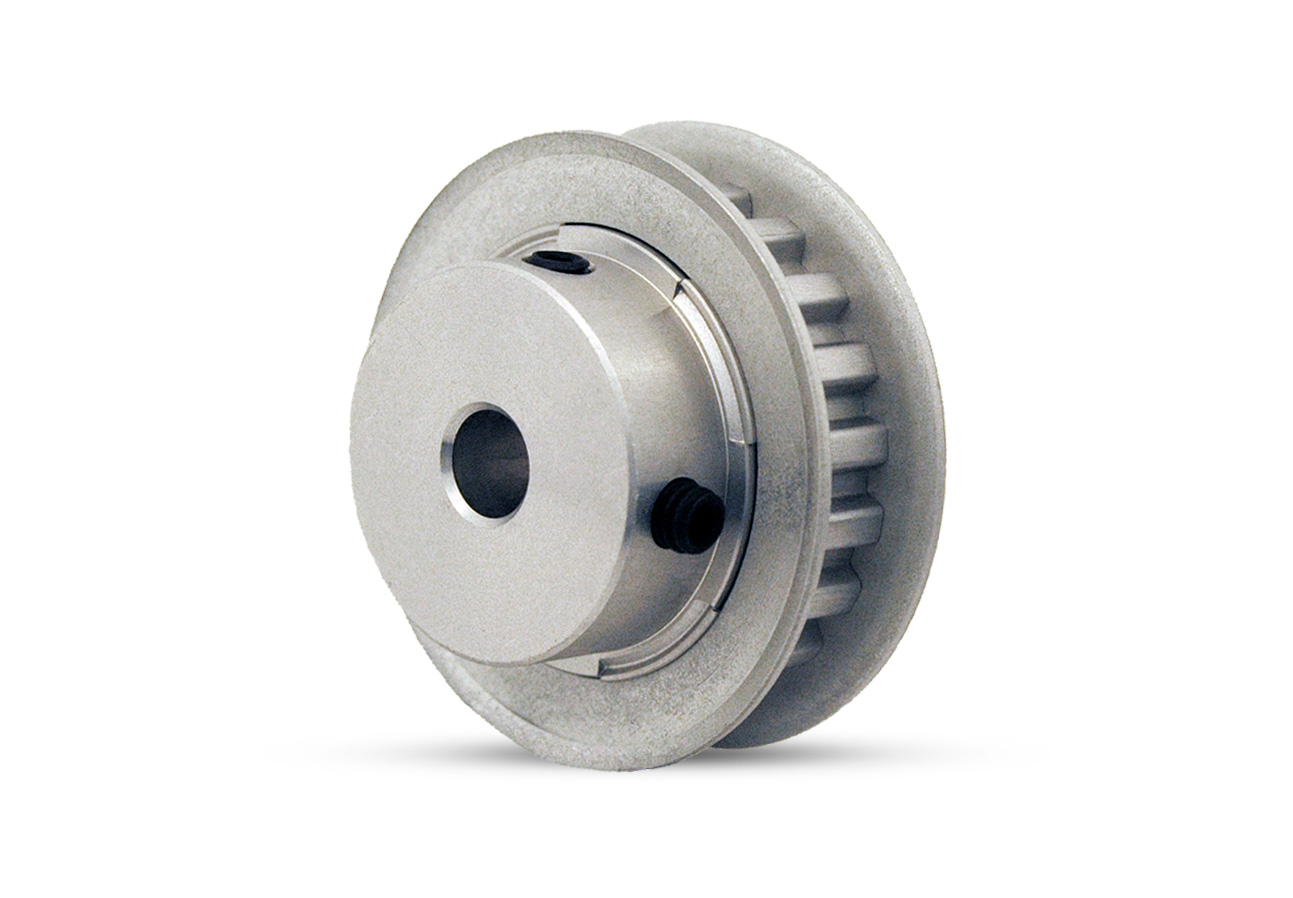

Product show

Manufacture process

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in single color box. If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages

before you pay the balance. Other payments terms, pls negotiate with us in advance, we can discuss.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 30 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.We welcome sample order.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type C |

| Manufacturing Process: | Cutting Tooth |

| Material: | Aluminum Alloy |

| Surface Treatment: | Polishing |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do XL pulleys compare to other pulley types, such as HTD or V-belt pulleys?

XL pulleys, HTD pulleys, and V-belt pulleys are all popular types of pulleys used in mechanical systems. Here is a detailed comparison of XL pulleys with HTD and V-belt pulleys:

1. Tooth Profile:

XL pulleys and HTD (High Torque Drive) pulleys both utilize toothed belts for power transmission. The main difference lies in their tooth profiles. XL pulleys have trapezoidal teeth, while HTD pulleys have a curvilinear tooth profile. V-belt pulleys, on the other hand, are designed for V-belts, which have a wider, wedge-shaped cross-section.

2. Power Transmission Capacity:

XL pulleys and HTD pulleys offer higher power transmission capacities compared to V-belt pulleys. The toothed belt designs of XL and HTD pulleys provide a positive engagement, preventing slippage under higher loads or torque. V-belt pulleys rely on friction between the belt and pulley, limiting their power transmission capacity.

3. Speed Capability:

XL pulleys and HTD pulleys are both suitable for higher speed applications compared to V-belt pulleys. The toothed belt designs allow for better grip and reduced belt slippage, enabling XL and HTD pulleys to operate at higher rotational speeds without compromising performance. V-belt pulleys are generally suitable for lower speed applications.

4. Efficiency:

XL pulleys and HTD pulleys offer higher efficiency compared to V-belt pulleys. The positive engagement between the toothed belts and pulleys in XL and HTD systems minimizes slippage and associated energy losses. V-belt pulleys, relying on friction, may experience higher energy losses due to belt slip.

5. Precision and Positioning:

XL pulleys and HTD pulleys provide better positional accuracy and reduced backlash compared to V-belt pulleys. The toothed belt systems offer improved control and synchronization, making them suitable for applications that require precise positioning or timing, such as robotics or CNC machines.

6. Noise and Vibration:

XL pulleys and HTD pulleys generally produce less noise and vibration compared to V-belt pulleys. The toothed belt systems exhibit smoother operation due to their positive engagement, reducing noise and vibration levels. V-belt pulleys may generate more noise and vibration due to potential slippage and belt oscillation.

7. Installation and Maintenance:

XL pulleys, HTD pulleys, and V-belt pulleys are all relatively easy to install and maintain. However, V-belt pulleys may require more frequent tension adjustments and periodic belt replacements due to belt wear and stretch. Toothed belt systems, including XL and HTD pulleys, often require less maintenance and offer longer belt life.

8. Application Suitability:

The choice between XL pulleys, HTD pulleys, and V-belt pulleys depends on the specific application requirements. XL and HTD pulleys are commonly used in industrial automation, power transmission, and precision machinery applications that demand higher torque, speed, and accuracy. V-belt pulleys are often employed in applications such as HVAC systems, automotive engines, and smaller machinery.

In summary, XL pulleys, HTD pulleys, and V-belt pulleys have differences in tooth profile, power transmission capacity, speed capability, efficiency, precision, noise/vibration levels, installation/maintenance, and application suitability. Understanding these differences is crucial in selecting the most appropriate pulley type for a given mechanical system and its specific requirements.

Are there safety considerations when working with XL pulley systems?

Yes, there are several safety considerations that should be taken into account when working with XL pulley systems. Here are some important safety considerations:

1. Lockout/Tagout Procedures:

Before performing any maintenance or repair tasks on a power transmission system involving XL pulleys, it is crucial to follow proper lockout/tagout procedures. This involves isolating the system from its power source and ensuring that it cannot be energized accidentally. Lockout/tagout procedures help prevent unexpected startup of the system, which could cause serious injuries.

2. Personal Protective Equipment (PPE):

Wear appropriate personal protective equipment when working with XL pulley systems. Depending on the specific task and potential hazards, PPE may include safety glasses, gloves, hearing protection, and protective clothing. PPE helps protect against potential injuries from contact with moving parts, flying debris, or noise exposure.

3. Training and Competence:

Ensure that personnel working with XL pulley systems are adequately trained and competent to perform their tasks safely. They should be familiar with the proper procedures for installation, operation, and maintenance of the pulleys. Training should also cover the identification and understanding of potential hazards associated with the system and how to mitigate them.

4. Machine Guards:

Install appropriate machine guards and protective enclosures around the XL pulley systems to prevent accidental contact with moving parts. Guards help minimize the risk of entanglement, pinch points, or injuries caused by the rotating pulleys or the timing belt.

5. Risk Assessment:

Conduct a thorough risk assessment of the XL pulley system and its surrounding environment. Identify and evaluate potential hazards, such as pinch points, sharp edges, or electrical hazards. Implement control measures to mitigate the identified risks, such as implementing interlocks, providing warning signs, or establishing safe work procedures.

6. Regular Maintenance:

Perform regular maintenance and inspection of the XL pulley system to ensure its safe operation. This includes checking for any signs of wear, damage, or misalignment, as well as verifying the integrity of guards and safety devices. Address any maintenance issues promptly to prevent potential safety hazards.

It is important to consult relevant safety standards, guidelines, and regulations specific to your industry and jurisdiction when working with XL pulley systems. Adhering to these safety considerations will help protect personnel from injuries and create a safe working environment when interacting with XL pulley systems.

What is an XL pulley, and how does it differ from other pulley types?

An XL pulley is a specific type of pulley commonly used in power transmission systems. It belongs to the family of timing belt pulleys, which are designed to work in conjunction with timing belts for precise motion control. Here are the key characteristics and differences of XL pulleys compared to other pulley types:

1. Tooth Profile:

XL pulleys have a tooth profile that is compatible with XL timing belts. The tooth profile is designed to accurately engage with the corresponding teeth on the timing belt, ensuring precise and synchronous motion transfer. The tooth profile of an XL pulley typically has a trapezoidal shape with a specific pitch and tooth height, which differs from other pulley types.

2. Pitch Size:

The pitch size of an XL pulley refers to the distance between adjacent tooth centers. XL pulleys have a pitch size of 0.200 inches (5.08 mm). This pitch size is standardized and ensures compatibility with XL timing belts of the same pitch, allowing for easy interchangeability and system design flexibility.

3. Belt Width Compatibility:

XL pulleys are designed to accommodate XL timing belts of specific widths. The belt width is determined by the application requirements and load considerations. XL pulleys are available in various groove widths to match the corresponding XL timing belt width, ensuring proper belt engagement and power transmission.

4. Material and Construction:

XL pulleys are commonly made from materials such as aluminum, steel, or plastic, depending on the application requirements. The choice of material affects the pulley’s durability, weight, and resistance to wear. The pulleys are typically precision-machined to ensure accurate tooth profiles, smooth operation, and reliable performance.

5. Application Range:

XL pulleys are widely used in applications that require precise motion control, such as robotics, CNC machines, 3D printers, and other automated systems. They are suitable for moderate to high torque requirements and can handle a range of speeds and loads, depending on the specific pulley size, material, and construction.

6. Interchangeability:

One of the advantages of XL pulleys is their interchangeability. Since they adhere to standardized pitch sizes and tooth profiles, XL pulleys from different manufacturers can be used interchangeably with XL timing belts of the same specifications. This interchangeability simplifies replacement, maintenance, and system upgrades.

In summary, an XL pulley is a type of timing belt pulley designed for precise motion control. It differs from other pulley types in terms of its tooth profile, pitch size, belt width compatibility, material and construction, application range, and interchangeability. Understanding these differences is crucial for selecting the appropriate pulley type for specific power transmission requirements.

editor by CX

2024-04-30