Product Description

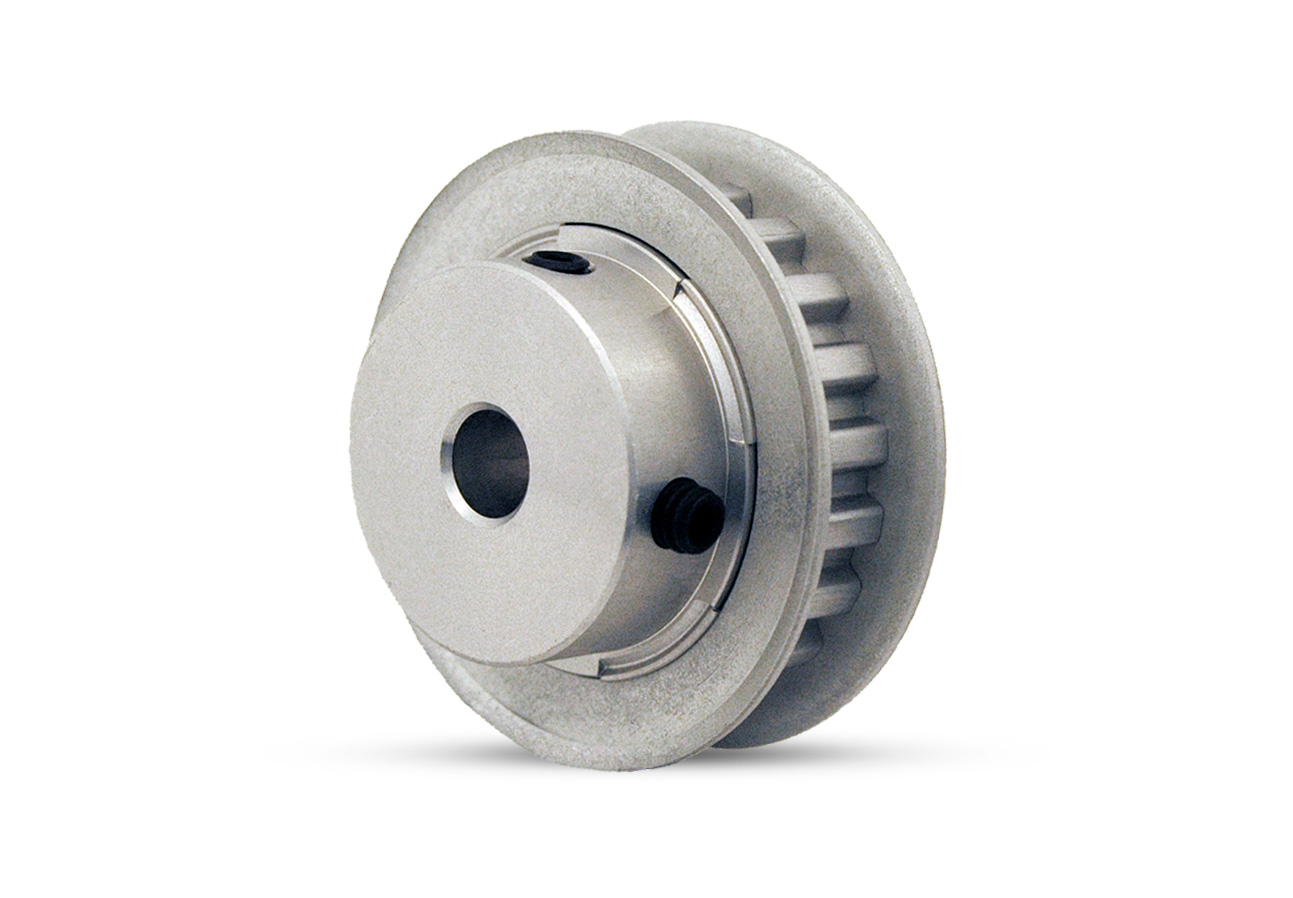

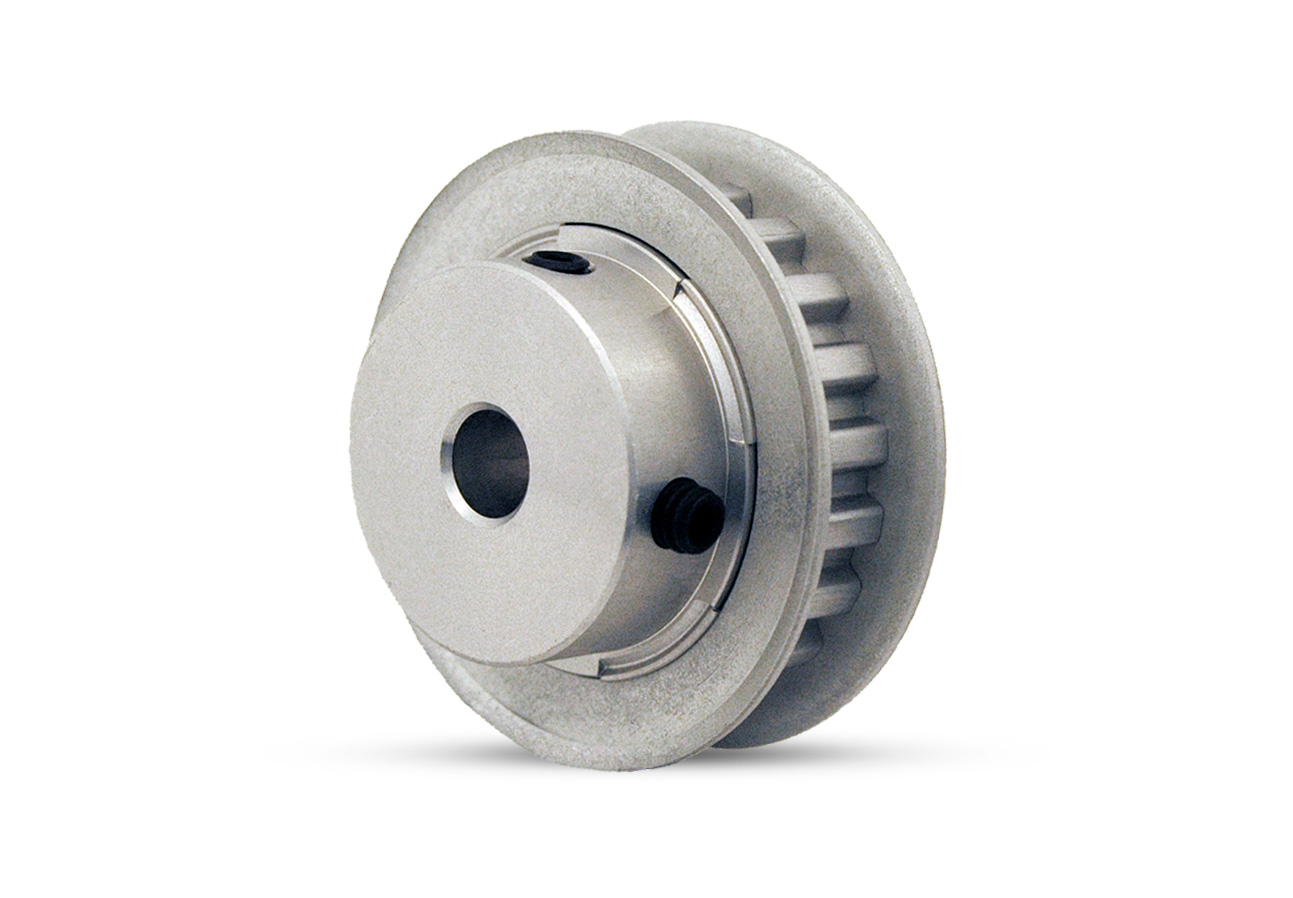

22-5M-15S-F-BL steel timing belt pulley htd 3m 5m 8m 14m timing pulley

Product Description

| Tooth profile | Trapezoidal toothed | MXL, XXL, XL, L, H, XH, XXH |

| T-toothed | T2.5, T5, T10, T20,AT5,AT10 | |

| Arc toothed | 3M, 5M, 8M, 14M | |

| Pitch | Metric | 2.5mm, 3mm, 5mm, 8mm, 10mm, 14mm, |

| Inch | 0.08″, 1/5″, 3/8″, 1/2″, 7/8″, | |

| Tooth No. | 10~216, Customized Available | |

| Bore Type | Plain Bore, Pilot Bore, Finished Bore, Taper Bushed Bore | |

| Belt width | Metric | 6mm, 9mm, 10mm, 15mm, 16mm, 20mm, 25mm, 30mm, 32mm, 40mm, 50mm, 55mm, 85mm, 115mm, 170mm |

| Inch | 1/4””, 3/8””, 1/2””, 3/4””, 1””, 1-1/2””, 2””, 3″, 4″ | |

| Pulley Construction | Solid, Web, Spoke | |

| Material | Aluminum, Alloy, Steel, Cast Iron | |

| Other Service | OEM/ODM Available, Huge Stock for standard pulleys | |

| Measuring System | Metric & Inch | |

| Surface treatment | Anodized/Black anodized/Hard anodized/Blacken/Zinc plating/Nickel plating/Chromium plating | |

| Accessories | We can provide supporting bearings, screws, expansion sleeve and other accessories services. | |

PACKING

| Packaging | |

| Packing

|

We use standard export wooden case, carton and pallet, but we can also pack it as per your special requirements. |

OUR COMPANY

ZheJiang Mighty Machinery Co., Ltd. specializes in offering best service and the most competitive price for our customer.

After over 10 years’ hard work, MIGHTY’s business has grown rapidly and become an important partner for oversea clients in the industrial field and become a holding company for 3 manufacturing factories.

MIGHTY’s products have obtained reputation of domestic and oversea customers with taking advantage of technology, management, quality and very competitive price.

Your satisfaction is the biggest motivation for our work, choose us to get high quality products and best service.

OUR FACTORY

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit.To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Htd 3m 5m 8m 14m |

| Material: | Steel/Cast Iron |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Teeth Number: | 28-216 Teeth |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can XL pulleys be customized or modified for specific industrial needs?

Yes, XL pulleys can be customized or modified to meet specific industrial needs. Here’s a detailed explanation of how XL pulleys can be tailored for specific requirements:

1. Size and Configuration:

XL pulleys can be customized in terms of size and configuration to match the requirements of different industrial applications. The diameter, width, and overall dimensions of the pulleys can be adjusted to accommodate specific belt sizes, space constraints, or desired power transmission ratios. Customization in size and configuration ensures optimal fit and performance within the given system.

2. Material Selection:

The choice of materials for XL pulleys can be customized based on the operating conditions and environmental factors of an industrial application. For example, if the pulleys will be exposed to corrosive chemicals, materials with high corrosion resistance, such as stainless steel or specialized coatings, can be selected. Customized material selection ensures the pulleys can withstand the specific demands of the application.

3. Surface Coatings and Treatments:

To enhance the performance and longevity of XL pulleys, various surface coatings and treatments can be applied. These include coatings for improved wear resistance, low friction coatings to reduce energy loss, or specialized treatments for better grip or bonding with the timing belt. Customized surface coatings and treatments allow for specific performance enhancements based on the industrial needs.

4. Timing Belt Compatibility:

XL pulleys can be customized to ensure compatibility with specific types of timing belts. This involves designing the pulley’s tooth profile, pitch, and tooth spacing to match the corresponding timing belt’s specifications. Customization in timing belt compatibility ensures optimal engagement between the pulleys and belts, resulting in efficient power transmission and reduced wear.

5. Specialty Features:

XL pulleys can be customized with specialty features to address unique industrial needs. These features may include integrated flanges for belt tracking, keyways or set screw holes for secure shaft attachment, custom hub configurations for easy mounting, or special profiles to accommodate additional accessories or components. Specialty features provide added functionality and convenience in specific industrial applications.

6. Performance Optimization:

By understanding the specific requirements of an industrial application, XL pulleys can be customized to optimize their performance. This may involve modifying the pulley’s geometry, tooth profile, or tooth count to achieve desired torque transmission, speed ratios, or power requirements. Performance optimization ensures efficient operation and reliable performance in the intended application.

The ability to customize or modify XL pulleys for specific industrial needs allows for tailored solutions that meet unique requirements. Manufacturers or designers work closely with customers to understand their application demands and provide customized pulleys that deliver optimal performance, reliability, and efficiency.

How do advancements in material technology influence the design of modern XL pulleys?

Advancements in material technology have a significant impact on the design of modern XL pulleys. Here’s a detailed explanation of how these advancements influence their design:

1. Enhanced Durability:

New materials with improved strength and durability allow for the design of XL pulleys that can withstand higher loads, operate at higher speeds, and have increased resistance to wear and fatigue. Advanced materials, such as high-strength alloys, composites, or specialized polymers, provide superior mechanical properties, enabling the design of more robust and long-lasting pulleys.

2. Weight Reduction:

Lightweight materials, such as carbon fiber composites or engineered polymers, contribute to the design of lightweight XL pulleys. Reduced weight in pulley systems offers advantages such as improved energy efficiency, reduced inertia, and lower overall system weight. This is particularly beneficial in applications where weight reduction is critical, such as aerospace, automotive, or portable machinery.

3. Corrosion Resistance:

New materials with excellent corrosion resistance properties, such as stainless steel or corrosion-resistant coatings, enable the design of XL pulleys suitable for harsh or corrosive environments. Corrosion-resistant pulleys are essential in industries such as marine, chemical processing, or outdoor applications where exposure to moisture, chemicals, or saltwater can cause degradation and premature failure.

4. Temperature Resistance:

Advancements in material technology have led to the development of materials that can withstand extreme temperatures. For applications involving high or low temperature environments, such as industrial ovens, furnaces, or cryogenic systems, the use of materials with superior temperature resistance ensures the pulleys maintain their performance and integrity under challenging operating conditions.

5. Noise and Vibration Damping:

New materials with inherent damping properties, such as elastomers or composite laminates, contribute to the design of XL pulleys that can effectively reduce noise and vibrations during operation. This is particularly important in applications that require low noise levels or where excessive vibrations can affect the performance and reliability of the system.

6. Customization and Flexibility:

Advancements in material technology provide designers with a wider range of options to tailor the properties of XL pulleys to specific application requirements. Materials can be formulated or engineered to meet specific needs such as high friction coefficients, electrical conductivity, or resistance to specific chemicals. This customization and flexibility in material selection allow for the optimization of pulley design and performance for various applications.

Overall, advancements in material technology have revolutionized the design of modern XL pulleys by offering improved durability, reduced weight, corrosion resistance, temperature resistance, noise and vibration damping, and customization options. Manufacturers can leverage these advancements to develop pulleys that meet the evolving needs of diverse industries and deliver enhanced performance and reliability.

What is an XL pulley, and how does it differ from other pulley types?

An XL pulley is a specific type of pulley commonly used in power transmission systems. It belongs to the family of timing belt pulleys, which are designed to work in conjunction with timing belts for precise motion control. Here are the key characteristics and differences of XL pulleys compared to other pulley types:

1. Tooth Profile:

XL pulleys have a tooth profile that is compatible with XL timing belts. The tooth profile is designed to accurately engage with the corresponding teeth on the timing belt, ensuring precise and synchronous motion transfer. The tooth profile of an XL pulley typically has a trapezoidal shape with a specific pitch and tooth height, which differs from other pulley types.

2. Pitch Size:

The pitch size of an XL pulley refers to the distance between adjacent tooth centers. XL pulleys have a pitch size of 0.200 inches (5.08 mm). This pitch size is standardized and ensures compatibility with XL timing belts of the same pitch, allowing for easy interchangeability and system design flexibility.

3. Belt Width Compatibility:

XL pulleys are designed to accommodate XL timing belts of specific widths. The belt width is determined by the application requirements and load considerations. XL pulleys are available in various groove widths to match the corresponding XL timing belt width, ensuring proper belt engagement and power transmission.

4. Material and Construction:

XL pulleys are commonly made from materials such as aluminum, steel, or plastic, depending on the application requirements. The choice of material affects the pulley’s durability, weight, and resistance to wear. The pulleys are typically precision-machined to ensure accurate tooth profiles, smooth operation, and reliable performance.

5. Application Range:

XL pulleys are widely used in applications that require precise motion control, such as robotics, CNC machines, 3D printers, and other automated systems. They are suitable for moderate to high torque requirements and can handle a range of speeds and loads, depending on the specific pulley size, material, and construction.

6. Interchangeability:

One of the advantages of XL pulleys is their interchangeability. Since they adhere to standardized pitch sizes and tooth profiles, XL pulleys from different manufacturers can be used interchangeably with XL timing belts of the same specifications. This interchangeability simplifies replacement, maintenance, and system upgrades.

In summary, an XL pulley is a type of timing belt pulley designed for precise motion control. It differs from other pulley types in terms of its tooth profile, pitch size, belt width compatibility, material and construction, application range, and interchangeability. Understanding these differences is crucial for selecting the appropriate pulley type for specific power transmission requirements.

editor by CX

2024-03-29