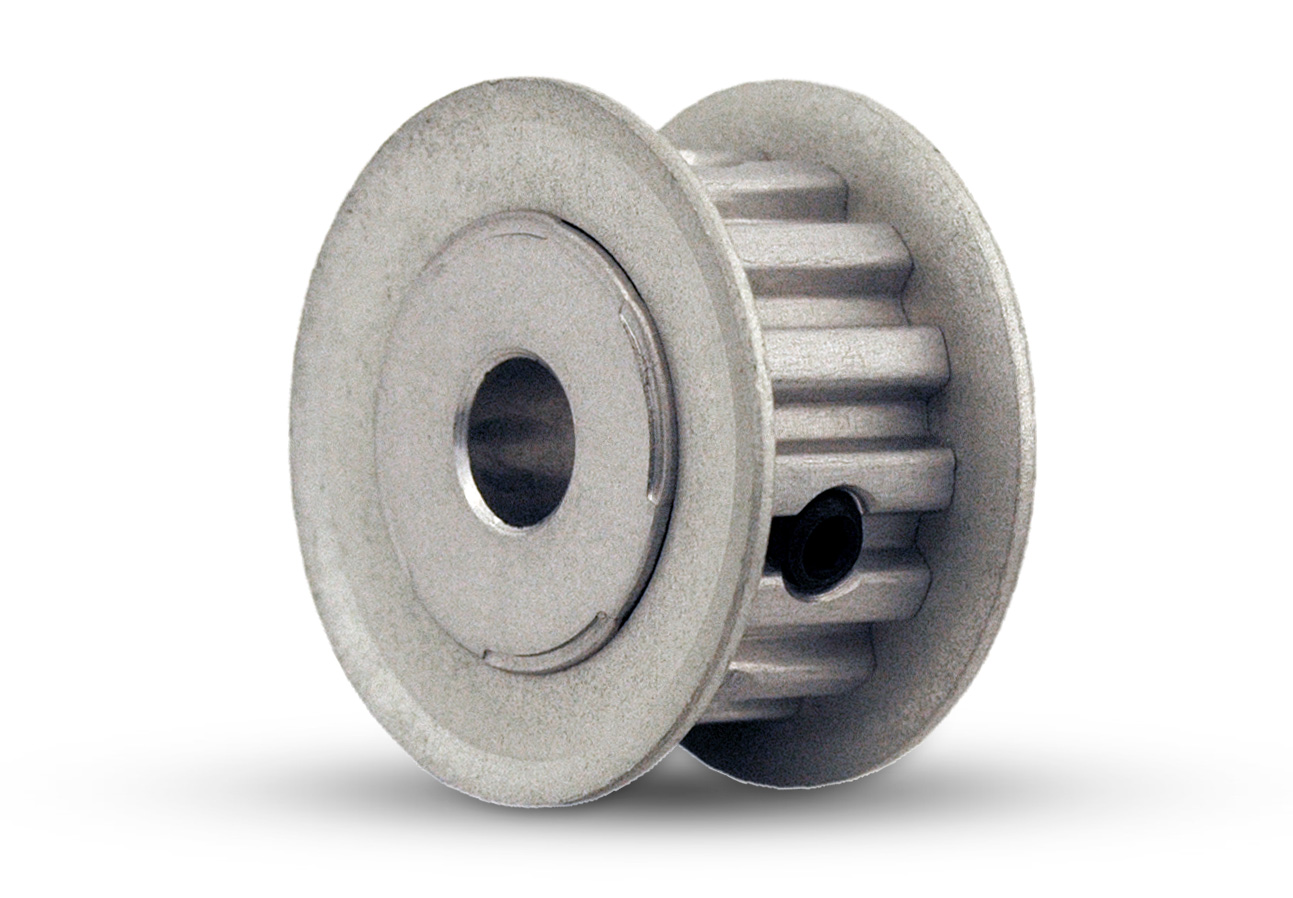

Product Description

INDUSTRIAL TIMING PULLEY

. Feature

Our Timing Belt uses Japan-imported high quality synthetic neoprene, high quality glass fiber cord and tooth surface with nylon 66 high stretch do the protection. The timing belt adapts teeth or teeth mesh to transfer power. It needs no lubrication, no slip, no pollution, less noise. The transmission efficiency is over 98%, and the speed ratio can reach 1:10. Linear velocity can be up to 50m/s. Its dynamic bending wind gives a good fatigue performance, and good aging heat-resistance abrasion performance.

. Parameters

Figure 1. Physicomechanical Property

| Item | Trapezoid Teeth | Arc Teeth | ||||||||

| XL | L | H | XH | XXH | 3M | 5M | 8M | 14M | 20M | |

| Tensile Strength N/mm | 80 | 120 | 270 | 380 | 450 | 90 | 160 | 300 | 400 | 520 |

| Elongation Reference at Loading N | 60 | 90 | 220 | 300 | 360 | 70 | 130 | 240 | 320 | 410 |

| Adhesion strength of cloth N/mm | 5 | 6.5 | 8 | 10 | 12 | – | 6 | 10 | 12 | 15 |

| Adhesion strength of core N/mm | 200 | 300 | 600 | 800 | 1500 | – | 400 | 700 | 1200 | 1600 |

| Gear shearing intensity N/mm | 50 | 60 | 70 | 75 | 90 | – | 50 | 60 | 80 | 100 |

| Elongation ≤ % | 4% | |||||||||

| Hardness Shore A | 75 ± 5 | |||||||||

Figure 2: Belt Teeth Size

| Type | Pitch (pb) mm | Tooth height (ht) mm | Belt thick (hs) mm | Angle |

| MXL | 2.032 | 0.51 | 1.14 | 40º |

| XXL | 3.175 | 0.76 | 1.52 | 40º |

| XL | 5.080 | 1.27 | 2.3 | 40º |

| L | 9.525 | 1.91 | 3.6 | 40º |

| H | 12.7 | 2.29 | 4.3 | 40º |

| XH | 22.225 | 6.35 | 11.2 | 40º |

| XXH | 31.7 | 9.53 | 15.7 | 40º |

| T2.5 | 2.5 | 0.7 | 1.3 | 40º |

| T5 | 5.0 | 1.2 | 2.2 | 40º |

| T10 | 10 | 2.5 | 4.5 | 40º |

| T20 | 20 | 5.0 | 8.0 | 40º |

| AT5 | 5.0 | 1.2 | 2.7 | 40º |

| AT10 | 10 | 2.5 | 5.0 | 40º |

| AT20 | 20 | 5.0 | 8.0 | 40º |

. Production Equipment

01, pulley CNC processing zone 02, synchronous belt making machine 03, synchronous round roll teeth processing zone

04, synchornous belt curing processing zone 05, 3 roll calender 06, direct drive belt forming machine

07, pulley workshop timing mould

. Quality Testing

FAQ

Q1. Can I have a sample order?

Yes, any sample order is welcome to know the quality of our products.

Q2. What about the lead time of the sample or the final order?

2-5 days for normal sample.

20-30 days for a formal order.

Q3. How much is the minimum quantity for each item in 1 order?

One mould quantity is ok. Usually around 100pcs for small item, several dozens for big item.

Q4. Is it possible to print our logo or brand on the belt?

Yes, we can print your logo or design on the belt after receipt of your formal authorization letter of the logo or your brand.

Q5. Do you offer the guarantee for your product?

Yes, usually we offer 1 year warranty for all of our products.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Electric Cars, Motorcycle, Car |

| Feature: | Wear-Resistant, High Temperature-Resistance |

| Tensile Strength: | Strong |

| Material: | Rubber |

| Type: | Toothed Belt |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do XL pulleys contribute to energy conservation and reduced friction in systems?

XL pulleys play a significant role in energy conservation and reducing friction in systems. Here is a detailed explanation of how XL pulleys contribute to these benefits:

1. Efficient Power Transmission:

XL pulleys are designed to transmit power from the driving source, such as an electric motor or engine, to the driven component, such as a conveyor belt or machine. By utilizing toothed belts, also known as timing belts, XL pulleys provide a positive engagement between the belt and pulley, ensuring efficient power transfer without slippage. This efficient power transmission minimizes energy loss, conserving energy in the system.

2. Reduced Friction:

XL pulleys, when used with compatible timing belts, offer low friction power transmission. The teeth on the pulleys mesh with the teeth on the timing belt, creating a positive engagement that reduces slippage and associated friction. The reduced friction between the pulleys and the belt results in improved efficiency, as less energy is wasted as heat and the overall system friction is minimized.

3. Proper Belt Tension:

XL pulleys contribute to energy conservation by facilitating proper belt tensioning. The accurate design and dimensions of the pulleys, combined with tensioning mechanisms, allow for optimal belt tension adjustment. Proper belt tension ensures the right balance between grip and flexibility, minimizing belt slip and energy loss due to excessive tension or slack.

4. Lightweight Design:

XL pulleys are often designed to be lightweight without compromising strength and durability. The use of lightweight materials, such as aluminum alloys or engineered polymers, reduces the rotational inertia of the pulleys. Lower rotational inertia requires less energy to accelerate or decelerate the pulleys, contributing to energy conservation and improved system responsiveness.

5. Smooth Operation:

XL pulleys, when manufactured with precision and high surface quality, enable smooth operation in power transmission systems. The even distribution of forces and reduced friction between the pulleys and timing belt result in reduced vibration, noise, and wear. Smooth operation minimizes energy loss due to mechanical inefficiencies and ensures the system operates at optimal performance levels.

6. System Optimization:

XL pulleys can be selected and designed to optimize system performance in terms of energy conservation and reduced friction. Factors such as the pulley size, tooth profile, and material selection can be tailored to match the specific system requirements. By optimizing the pulley design and characteristics, energy losses and friction can be minimized, leading to improved overall system efficiency.

In summary, XL pulleys contribute to energy conservation and reduced friction in systems through efficient power transmission, reduced friction between pulleys and belts, proper belt tensioning, lightweight design, smooth operation, and system optimization. By utilizing these features, XL pulleys help minimize energy wastage, improve system efficiency, and reduce friction-related wear and tear, ultimately leading to energy savings and increased operational lifespan of the system.

What are the advantages of using XL pulleys in power transmission systems?

XL pulleys offer several advantages when used in power transmission systems. Here are some of the key advantages:

1. Precise Motion Control:

XL pulleys, along with their corresponding timing belts, provide precise motion control in power transmission systems. The teeth on the pulleys engage with the teeth on the belt, resulting in accurate and repeatable positioning. This makes XL pulleys suitable for applications that require precise speed and position control, such as robotics, CNC machines, and automation systems.

2. High Efficiency:

The toothed profile of XL pulleys enables efficient power transmission with minimal energy loss. The positive engagement between the pulley and the timing belt reduces slippage and ensures a high level of efficiency in transferring rotational motion. This efficiency is particularly advantageous in applications where power efficiency is critical, as it helps reduce energy consumption and improves overall system performance.

3. Wide Range of Speed Ratios:

XL pulleys are available in various tooth counts, allowing for a wide range of speed ratios in power transmission systems. By selecting different pulley sizes or combinations, the rotational speed can be adjusted to match the specific requirements of the application. This flexibility in speed ratios makes XL pulleys versatile and adaptable to different speed and torque requirements.

4. Low Noise and Vibration:

XL pulleys and timing belts operate with minimal noise and vibration compared to other power transmission methods, such as gears or chain drives. The toothed design reduces backlash and ensures smooth and quiet operation. This advantage is particularly beneficial in applications that require low noise levels, precision, and reduced mechanical vibrations.

5. Maintenance-Free Operation:

XL pulleys and timing belts are typically maintenance-free components. Unlike traditional belt drives that require regular tension adjustments or lubrication, XL pulleys and belts do not require periodic maintenance. This reduces the overall maintenance costs and improves the reliability of the power transmission system.

6. Compact and Lightweight:

XL pulleys are compact and lightweight compared to some alternative power transmission components, such as gears or chain drives. This compactness allows for space-saving designs and makes them suitable for applications with limited space or weight restrictions.

Overall, XL pulleys offer precise motion control, high efficiency, a wide range of speed ratios, low noise and vibration, maintenance-free operation, and compactness. These advantages make XL pulleys a popular choice in various power transmission systems across industries.

How do XL pulleys enhance the precision and efficiency of mechanical systems?

XL pulleys play a crucial role in enhancing the precision and efficiency of mechanical systems by providing precise motion control and efficient power transmission. Here are the key ways in which XL pulleys contribute to the improvement of mechanical systems:

1. Accurate Motion Control:

XL pulleys, when used in conjunction with timing belts, enable accurate and synchronized motion control. The tooth profile of XL pulleys is designed to match the tooth profile of the timing belt, ensuring precise engagement and motion transfer. This accuracy in motion control allows mechanical systems to achieve precise positioning, movement, and coordination of components.

2. Positioning Accuracy:

By providing precise motion control, XL pulleys contribute to positioning accuracy in mechanical systems. Whether it’s a robotic arm, a CNC machine tool, or a 3D printer, the precise movement enabled by XL pulleys ensures that components or tools are positioned with high accuracy, resulting in the desired output or product quality.

3. Repeatability:

XL pulleys facilitate consistent and repeatable motion in mechanical systems. The accurate engagement between the pulleys and timing belts ensures that the same motion is reproduced reliably each time. This repeatability is essential in applications where consistent results are required, such as in manufacturing processes or automated systems.

4. Reduced Backlash:

Backlash refers to the undesired clearance or play between mating components, which can cause inaccuracies and imprecise motion. XL pulleys, with their precise tooth engagement with timing belts, minimize backlash in mechanical systems. This reduction in backlash improves the overall precision and eliminates unwanted movement or positioning errors.

5. Efficiency in Power Transmission:

XL pulleys, when combined with properly sized timing belts, offer efficient power transmission in mechanical systems. The toothed nature of the pulleys and belts allows for high torque transfer, minimizing slippage and ensuring reliable power delivery. This efficiency in power transmission maximizes the utilization of energy and reduces energy losses, resulting in improved overall system efficiency.

6. Interchangeability and Flexibility:

XL pulleys adhere to standardized dimensions and tooth profiles, allowing for interchangeability between different manufacturers. This interchangeability provides flexibility in system design, maintenance, and upgrades. It also simplifies the replacement of pulleys, which can be beneficial in minimizing downtime and reducing costs.

7. Load Handling Capability:

XL pulleys are designed to handle moderate to high torque requirements. This load handling capability makes them suitable for various applications that require robust and reliable power transmission, such as in heavy machinery, automation systems, or industrial equipment.

By enhancing precision in motion control, improving efficiency in power transmission, and offering flexibility in system design, XL pulleys contribute to the overall performance and reliability of mechanical systems. They enable accurate positioning, repeatable motion, and efficient energy transfer, leading to improved productivity, quality, and operational efficiency.

editor by CX

2024-05-08