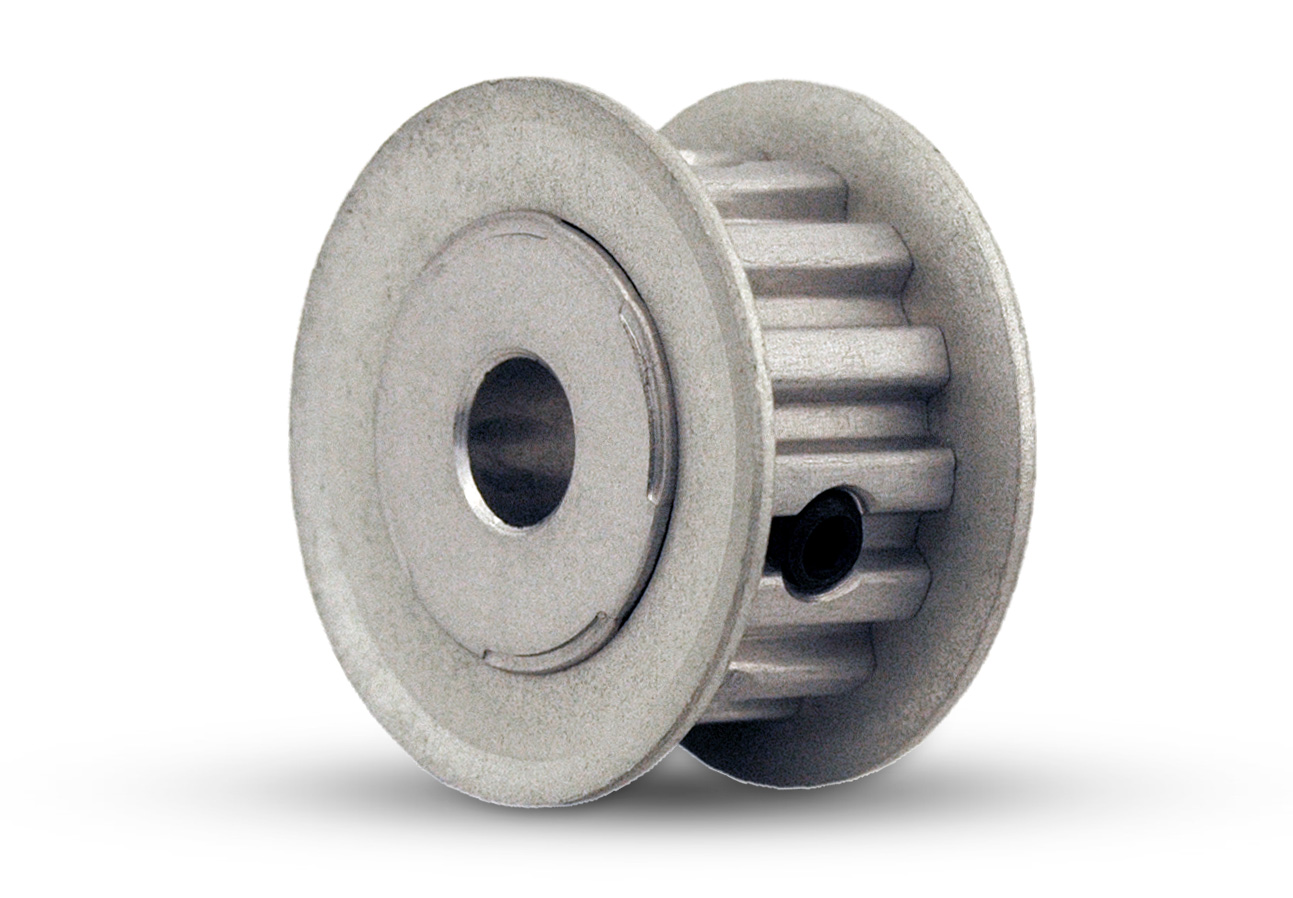

Product Description

Factory high quality Aluminum alloy 5mm bore 2 flanges GT2 GT3 GT5 GT8 GT14 timing belt pulleys

1) Warranty: our timing pulley’s quality is very good and with ensurance within 1 year, when you receive the products and find quality problems, we promise you could return it back and free maintenance.

2) Drawings: please send you timing pulleys’ drawings to us to get the best quotation; If you have no drawings, then we could work out CAD drawings and the best quotation to you ASAP.

3) Sample: we accept 1 piece sample’s order, we could do samples until you’re satisfied.

4) Confidentiality agreetment: Strictly adherence to client confidentiality agreetment for timing pulleys.

| Product Description |

|

Product Name |

Timing Belt Pulley | |

| Teeth profile | Trapezoidal toothed | MXL, XXL, XL, L, H, XH, XXH |

| T-toothed | T2.5, T5, T10, T20 | |

| Arc toothed | HTD3M, HTD5M, HTD8M, HTD14M, HTD20M, Gt2, Gt3, Gt5 | |

| S-toothed | S2M, S3M, S4.5M, S5M, S8M, S14M | |

| Parabolic-toothed | P2M, P3M, P5M, P8M, P14M | |

| Y-toothed | G2M, G3M, G5M, Y8M | |

| Teeth Quantity | 10-150 teeth or customized | |

| Inner Bore | 2-200mm H7 precision or customized | |

| Belt width | 4mm, 6mm, 9mm, 10mm, 12mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 1/4”, 5/16”, 3/8”, 1/2”, 3/4”, 1”, 1.5”, 2”or customized | |

| Accessories | We can provide the service of assembling setscrews, bearings, shafts or taper bush | |

| Surface treatment | Anodize,Black Oxide,Phosphate and Galvanization | |

| Drawing Format | Timing belt pulley cad drawing,timing belt pulley UG drawing,Timing belt Pulley Soliwork drawing,Timing Pulley PDF drawing | |

What is timing pulley?

Timing pulleys are specialized pulleys that have either teeth or pockets around the outside diameter of the pulley body. Timing teeth engage holes in the metal belt, while timing pockets engage drive lugs on a belt’s inner circumference. These teeth or pockets are used only for timing, not for power transmission.

How timing pulleys work?

The synchronous wheel transmission is composed of an endless belt with equal-spaced teeth on the inner peripheral surface and a pulley with corresponding teeth. During operation, the toothed teeth mesh with the tooth grooves of the pulley to transmit motion and power, which is integrated with the belt. A new type of belt drive with the advantages of transmission, chain drive and gear transmission.

What is gt2 timing pulley?

2mm pitch GT2 Pulley. The GT2 or 2GT Tooth Profile timing pulley prevails in the 3d printing hobby cause the Round tooth profile brings high precision of non-backlash, were known as today’s Reprap Pulley.

What is a timing pulley flange?

Timing pulley flanges are used to maintain belt contact with a timing pulley in power transmission applications.Timing pulley flanges are manufactured to fit timing pulleys of the same pitch and size. The dimensions of a pitch, including the mating flange, are specified by the number of grooves.

What are synchronous belts used for?

The trapezoidal tooth profile first used on synchronous belts is recognized as standard. Belts with this configuration are commonly used in machine tools, textile machinery, home appliances, business equipment, and as camshaft drives in engines.

Note:Please confirm you need teeth profile, teeth quantity, belt width, bore diameter, quantity and type (please refer below drawings) to get our the most complete CAD drawings and the best quotation.

Related Products

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Iron |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do XL pulleys contribute to energy conservation and reduced friction in systems?

XL pulleys play a significant role in energy conservation and reducing friction in systems. Here is a detailed explanation of how XL pulleys contribute to these benefits:

1. Efficient Power Transmission:

XL pulleys are designed to transmit power from the driving source, such as an electric motor or engine, to the driven component, such as a conveyor belt or machine. By utilizing toothed belts, also known as timing belts, XL pulleys provide a positive engagement between the belt and pulley, ensuring efficient power transfer without slippage. This efficient power transmission minimizes energy loss, conserving energy in the system.

2. Reduced Friction:

XL pulleys, when used with compatible timing belts, offer low friction power transmission. The teeth on the pulleys mesh with the teeth on the timing belt, creating a positive engagement that reduces slippage and associated friction. The reduced friction between the pulleys and the belt results in improved efficiency, as less energy is wasted as heat and the overall system friction is minimized.

3. Proper Belt Tension:

XL pulleys contribute to energy conservation by facilitating proper belt tensioning. The accurate design and dimensions of the pulleys, combined with tensioning mechanisms, allow for optimal belt tension adjustment. Proper belt tension ensures the right balance between grip and flexibility, minimizing belt slip and energy loss due to excessive tension or slack.

4. Lightweight Design:

XL pulleys are often designed to be lightweight without compromising strength and durability. The use of lightweight materials, such as aluminum alloys or engineered polymers, reduces the rotational inertia of the pulleys. Lower rotational inertia requires less energy to accelerate or decelerate the pulleys, contributing to energy conservation and improved system responsiveness.

5. Smooth Operation:

XL pulleys, when manufactured with precision and high surface quality, enable smooth operation in power transmission systems. The even distribution of forces and reduced friction between the pulleys and timing belt result in reduced vibration, noise, and wear. Smooth operation minimizes energy loss due to mechanical inefficiencies and ensures the system operates at optimal performance levels.

6. System Optimization:

XL pulleys can be selected and designed to optimize system performance in terms of energy conservation and reduced friction. Factors such as the pulley size, tooth profile, and material selection can be tailored to match the specific system requirements. By optimizing the pulley design and characteristics, energy losses and friction can be minimized, leading to improved overall system efficiency.

In summary, XL pulleys contribute to energy conservation and reduced friction in systems through efficient power transmission, reduced friction between pulleys and belts, proper belt tensioning, lightweight design, smooth operation, and system optimization. By utilizing these features, XL pulleys help minimize energy wastage, improve system efficiency, and reduce friction-related wear and tear, ultimately leading to energy savings and increased operational lifespan of the system.

Are there safety considerations when working with XL pulley systems?

Yes, there are several safety considerations that should be taken into account when working with XL pulley systems. Here are some important safety considerations:

1. Lockout/Tagout Procedures:

Before performing any maintenance or repair tasks on a power transmission system involving XL pulleys, it is crucial to follow proper lockout/tagout procedures. This involves isolating the system from its power source and ensuring that it cannot be energized accidentally. Lockout/tagout procedures help prevent unexpected startup of the system, which could cause serious injuries.

2. Personal Protective Equipment (PPE):

Wear appropriate personal protective equipment when working with XL pulley systems. Depending on the specific task and potential hazards, PPE may include safety glasses, gloves, hearing protection, and protective clothing. PPE helps protect against potential injuries from contact with moving parts, flying debris, or noise exposure.

3. Training and Competence:

Ensure that personnel working with XL pulley systems are adequately trained and competent to perform their tasks safely. They should be familiar with the proper procedures for installation, operation, and maintenance of the pulleys. Training should also cover the identification and understanding of potential hazards associated with the system and how to mitigate them.

4. Machine Guards:

Install appropriate machine guards and protective enclosures around the XL pulley systems to prevent accidental contact with moving parts. Guards help minimize the risk of entanglement, pinch points, or injuries caused by the rotating pulleys or the timing belt.

5. Risk Assessment:

Conduct a thorough risk assessment of the XL pulley system and its surrounding environment. Identify and evaluate potential hazards, such as pinch points, sharp edges, or electrical hazards. Implement control measures to mitigate the identified risks, such as implementing interlocks, providing warning signs, or establishing safe work procedures.

6. Regular Maintenance:

Perform regular maintenance and inspection of the XL pulley system to ensure its safe operation. This includes checking for any signs of wear, damage, or misalignment, as well as verifying the integrity of guards and safety devices. Address any maintenance issues promptly to prevent potential safety hazards.

It is important to consult relevant safety standards, guidelines, and regulations specific to your industry and jurisdiction when working with XL pulley systems. Adhering to these safety considerations will help protect personnel from injuries and create a safe working environment when interacting with XL pulley systems.

Can you explain the key characteristics and specifications of XL pulleys?

XL pulleys have specific characteristics and specifications that are important to understand for their proper selection and use. Here are the key details:

1. Tooth Profile:

XL pulleys have a tooth profile designed to work with XL timing belts. The tooth profile is trapezoidal in shape, with specific dimensions and angles to ensure precise engagement with the corresponding teeth on the timing belt.

2. Pitch Size:

The pitch size of an XL pulley refers to the distance between adjacent tooth centers. XL pulleys have a standardized pitch size of 0.200 inches (5.08 mm). This pitch size ensures compatibility with XL timing belts of the same pitch, allowing for easy interchangeability.

3. Belt Width Compatibility:

XL pulleys are designed to accommodate XL timing belts of specific widths. The belt width is determined by the application requirements and load considerations. XL pulleys are available in various groove widths to match the corresponding XL timing belt width, ensuring proper belt engagement and power transmission.

4. Material and Construction:

XL pulleys are commonly made from materials such as aluminum, steel, or plastic. The choice of material depends on factors like the application requirements, load capacity, and cost considerations. The pulleys are precision-machined to ensure accurate tooth profiles, smooth operation, and reliable performance.

5. Number of Teeth:

The number of teeth on an XL pulley determines the speed ratio and the positioning accuracy of the motion control system. The number of teeth can vary depending on the specific application requirements and the desired speed and torque ratios.

6. Flange Options:

XL pulleys may come with flanges on one or both sides. Flanges provide additional support to the timing belt, preventing it from slipping off the pulley during operation. The presence and configuration of flanges depend on the specific application needs and the desired level of belt stability.

7. Application Range:

XL pulleys are suitable for applications that require precise motion control, such as robotics, CNC machines, 3D printers, and other automated systems. They can handle moderate to high torque requirements and operate at various speeds, depending on the specific pulley size, material, and construction.

8. Interchangeability:

Due to standardized pitch sizes and tooth profiles, XL pulleys from different manufacturers are interchangeable with XL timing belts of the same specifications. This interchangeability simplifies replacement, maintenance, and system upgrades.

Understanding these key characteristics and specifications of XL pulleys is essential for selecting the right pulley for a given application, ensuring proper power transmission, and achieving accurate motion control.

editor by CX

2024-05-07