Product Description

Product Description

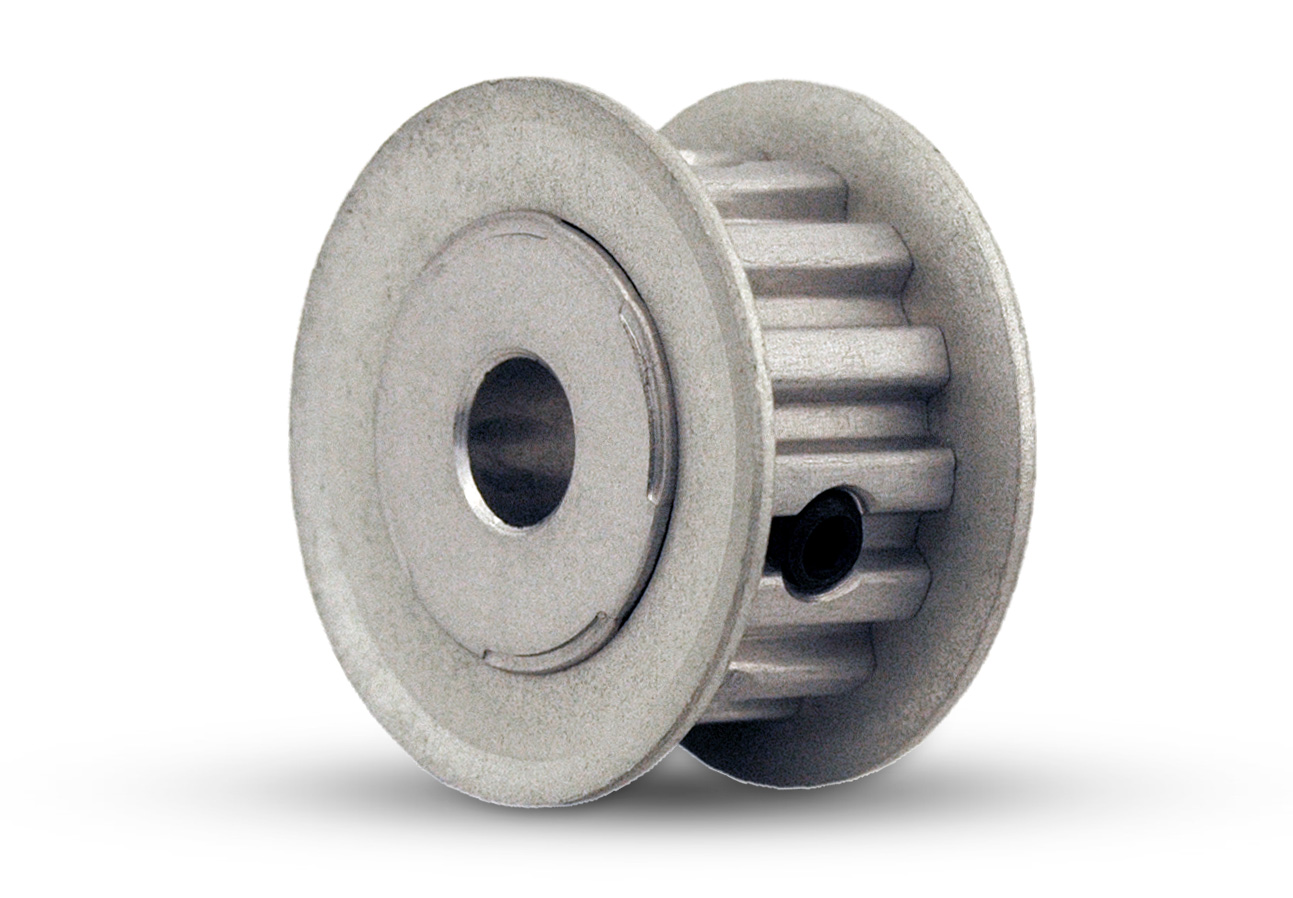

Detailed Product Description

V-Pulley, V-Belt Pulley, Timing Pulley, Taper bush Pulley, Pilot Pulley, from 1 groove to 8 groove, customized Pulle

Pulley:

1. V-belt pulley:

European Standard: V-belt pulley for taper bushes: SPZ, SPA, SPB, SPC, up to 10 grooves

American Standard: Sheaves for taperbushes and QD bushes: 3V, 5V, 8V

Bore: Pilot bore, finish bore, taper bore, bore for QD bush

2. Models: L037, L050, L075, L100, H075, H100, H150, H200, H300, XH200, XH300, XH400

HTD: 3M-09, 3M-15, 5M-09, 5M-15, 5M-25, 8M-20, 8M-30, 8M-50, 8M-85, 14M-40, 14M-55, 14M-85, 14M-115, 14M-170, T2.5, T5, T10, T20, AT2.5, AT5, AT10, AT20 Pilot bore, taper bore, QD bore

Material: 1045 steel, aluminum and stainless steel

Surface finish: Black oxidized phosphate, anodized, zinc-plated

Standard toothed bars are also available.

Detailed Photos

Product Parameters

Our Advantages

| WHY CHOOSE US |

| Comprehensive Product Portfolio We produce and supply a wide range of power transmission products including drive chains, leaf chains, conveyor chains, agricultural chains, sprockets, and couplings. This one-store-for-all shopping experience will significantly reduce your searching costs while guarantee youfind what you want at 1 click. Value Choice Products Our products are the best combination of quality and price, and you get what Seasoned Sales Associates and Engineers We have 15 seasoned sales associates and 5 engineers; 100% Customer Retention Rate Our regular customers from overseas come back not just for our |

| FAQ |

| Q1: What’s your average lead time? A: It varies. Our regular end-to-end lead time is 1-2 months.. We also provide express shipments for rush orders. For details,please consult our sales associate. Q2: Is your price better than your competitors given the same quality? Q4: Can we inspect the goods before shipment? Q5: What kind of payment method is acceptable for your mill? Q6: What if I have any other questions? |

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Type E |

| Manufacturing Process: | Casting |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do XL pulleys contribute to energy conservation and reduced friction in systems?

XL pulleys play a significant role in energy conservation and reducing friction in systems. Here is a detailed explanation of how XL pulleys contribute to these benefits:

1. Efficient Power Transmission:

XL pulleys are designed to transmit power from the driving source, such as an electric motor or engine, to the driven component, such as a conveyor belt or machine. By utilizing toothed belts, also known as timing belts, XL pulleys provide a positive engagement between the belt and pulley, ensuring efficient power transfer without slippage. This efficient power transmission minimizes energy loss, conserving energy in the system.

2. Reduced Friction:

XL pulleys, when used with compatible timing belts, offer low friction power transmission. The teeth on the pulleys mesh with the teeth on the timing belt, creating a positive engagement that reduces slippage and associated friction. The reduced friction between the pulleys and the belt results in improved efficiency, as less energy is wasted as heat and the overall system friction is minimized.

3. Proper Belt Tension:

XL pulleys contribute to energy conservation by facilitating proper belt tensioning. The accurate design and dimensions of the pulleys, combined with tensioning mechanisms, allow for optimal belt tension adjustment. Proper belt tension ensures the right balance between grip and flexibility, minimizing belt slip and energy loss due to excessive tension or slack.

4. Lightweight Design:

XL pulleys are often designed to be lightweight without compromising strength and durability. The use of lightweight materials, such as aluminum alloys or engineered polymers, reduces the rotational inertia of the pulleys. Lower rotational inertia requires less energy to accelerate or decelerate the pulleys, contributing to energy conservation and improved system responsiveness.

5. Smooth Operation:

XL pulleys, when manufactured with precision and high surface quality, enable smooth operation in power transmission systems. The even distribution of forces and reduced friction between the pulleys and timing belt result in reduced vibration, noise, and wear. Smooth operation minimizes energy loss due to mechanical inefficiencies and ensures the system operates at optimal performance levels.

6. System Optimization:

XL pulleys can be selected and designed to optimize system performance in terms of energy conservation and reduced friction. Factors such as the pulley size, tooth profile, and material selection can be tailored to match the specific system requirements. By optimizing the pulley design and characteristics, energy losses and friction can be minimized, leading to improved overall system efficiency.

In summary, XL pulleys contribute to energy conservation and reduced friction in systems through efficient power transmission, reduced friction between pulleys and belts, proper belt tensioning, lightweight design, smooth operation, and system optimization. By utilizing these features, XL pulleys help minimize energy wastage, improve system efficiency, and reduce friction-related wear and tear, ultimately leading to energy savings and increased operational lifespan of the system.

How does the size of an XL pulley impact its load-bearing capacity?

The size of an XL pulley plays a significant role in determining its load-bearing capacity. Here’s how the size of an XL pulley impacts its load-bearing capacity:

1. Surface Area:

The size of the pulley affects the surface area over which the force is distributed. Larger pulleys generally have a larger surface area, allowing for better force distribution and reducing the stress concentration on the pulley. This increased surface area helps in handling higher loads and reduces the risk of pulley failure.

2. Moment Arm:

The size of the pulley also affects the moment arm, which is the perpendicular distance from the center of the pulley to the line of action of the force. A larger pulley typically has a longer moment arm, resulting in a larger torque or moment applied to the pulley. This increased torque capacity allows the pulley to handle higher loads without experiencing excessive deflection or failure.

3. Tooth Engagement:

XL pulleys transmit power through the engagement of their teeth with the corresponding teeth on the timing belt. The size of the pulley determines the number of teeth and the contact area between the pulley and the belt. A larger pulley with more teeth provides increased contact area and better tooth engagement, resulting in improved load-bearing capacity and power transmission efficiency.

4. Material Strength:

The size of the pulley can also impact the selection of materials with appropriate strength properties. Larger pulleys may require materials with higher strength to withstand the increased loads. The choice of materials with adequate tensile strength, fatigue resistance, and durability becomes crucial in ensuring the load-bearing capacity of the pulley.

5. Speed and Torque:

The size of the pulley influences the speed and torque characteristics of the system. Larger pulleys can accommodate larger belts, resulting in increased belt contact surface and improved power transmission. This allows for higher torque transfer capabilities, enabling the pulley to handle heavier loads.

It’s important to note that while larger pulleys generally have higher load-bearing capacities, other factors such as material properties, design considerations, and proper installation also influence the overall load capacity of the pulley system. Therefore, it is essential to consult the manufacturer’s guidelines and engineering calculations to determine the appropriate pulley size and ensure safe operation under the desired load conditions.

What materials are typically used in the construction of XL pulleys?

The construction of XL pulleys involves the use of various materials, depending on the specific application requirements, load capacity, and cost considerations. Here are the materials commonly used in the construction of XL pulleys:

1. Aluminum:

Aluminum is a lightweight and corrosion-resistant material commonly used in XL pulleys. It offers good strength-to-weight ratio and excellent machinability, making it suitable for many applications. Aluminum pulleys are often used in robotics, automation systems, and other applications where weight reduction is desirable.

2. Steel:

Steel is a durable and robust material used in XL pulleys for applications that require higher load capacity and strength. Steel pulleys provide excellent resistance to wear and can handle heavy-duty applications. They are commonly used in industrial machinery, automotive components, and other demanding applications.

3. Plastic:

Plastic pulleys are lightweight, cost-effective, and offer good resistance to chemicals and corrosion. They are commonly made from materials such as nylon, acetal, or polycarbonate. Plastic pulleys are used in a variety of applications, including 3D printers, medical devices, and smaller-scale machinery.

4. Composite Materials:

Composite materials, such as fiberglass-reinforced polymers, are sometimes used in the construction of XL pulleys. These materials offer a combination of properties, including high strength, low weight, and resistance to corrosion. Composite pulleys are often used in aerospace, marine, and other specialized applications.

5. Stainless Steel:

Stainless steel is chosen for XL pulleys when corrosion resistance is of utmost importance. Stainless steel pulleys exhibit excellent resistance to rust and corrosion, making them suitable for applications in harsh environments or where exposure to moisture or chemicals is expected.

It’s important to note that the material selection for XL pulleys depends on factors such as the application requirements, load capacity, environmental conditions, and budget constraints. Manufacturers consider these factors to determine the most suitable material for achieving the desired performance and reliability in specific applications.

editor by CX

2023-11-13